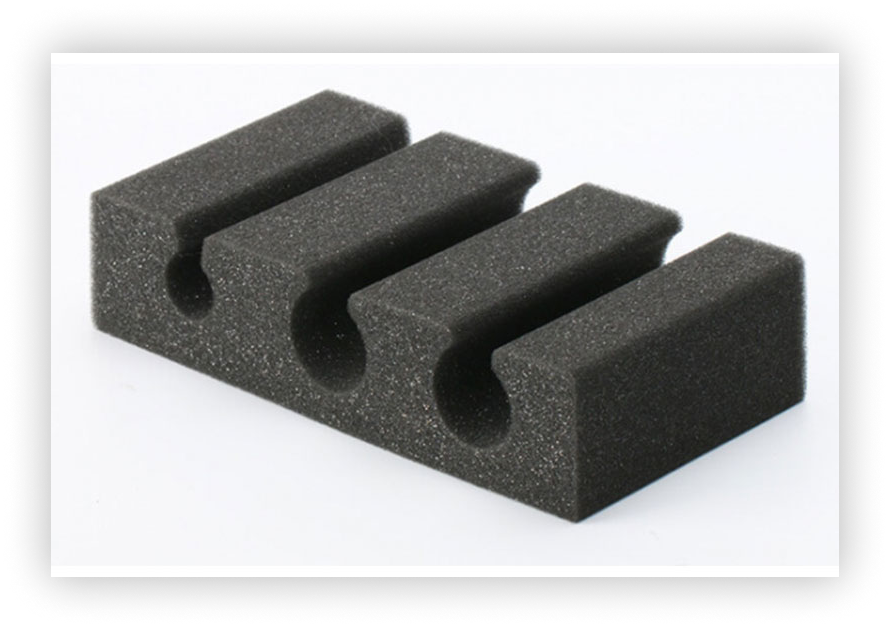

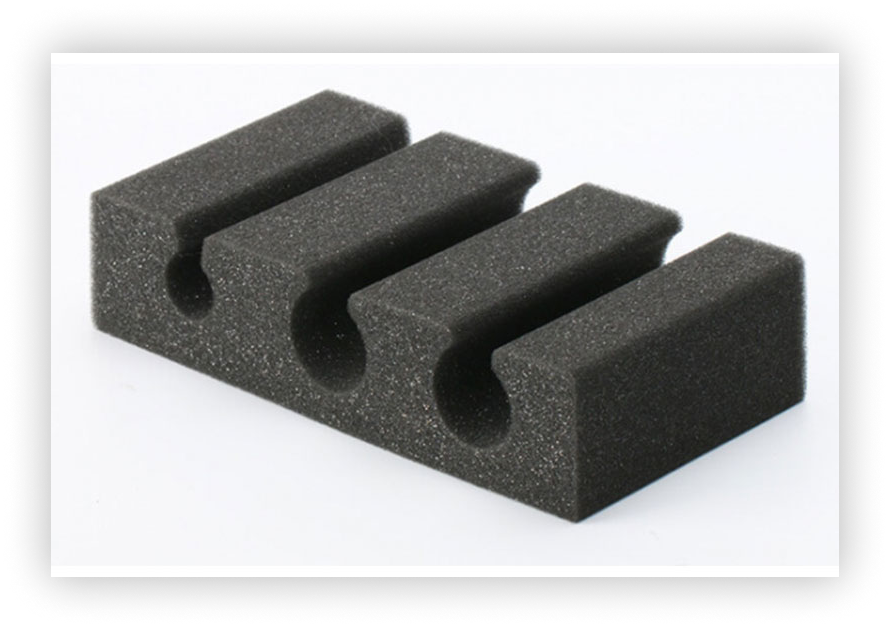

Сontour cutting

Contour cutting of foam rubber is carried out using a high-precision cutting machine with CNC (computer numerical control). Products are cut according to the presented drawing according to any profile. Cutting is carried out on the surface: you can get rectangular, cylindrical parts or arbitrary two-dimensional shapes.

Advantages

Profitability. When cutting and joining contour parts, no waste is generated directly at the furniture production itself.

Ease of manufacture. You get a finished part of a complex contour, which you use when assembling the product without further processing. This means that in the manufacture of parts from foam rubber, no additional costs are foreseen.

Modern sofas, as a rule, are complemented by zippered pillows so that you can remove the cover and wash it. Contour-cut foam seats make this possible. Moreover, with such additions, the furniture looks more presentable. When gluing sheets together, it is impossible to achieve a holistic view of interior items.